What Does

Phenolic Gasket Mean?

A phenolic gasket is part of a flange isolation kit that is designed to operate in a pipeline by providing electrical isolation in cathodic protection (CP) systems with flange isolation. By resisting oil, water and salts, they are an essential tool to minimize future damage of the pipeline.

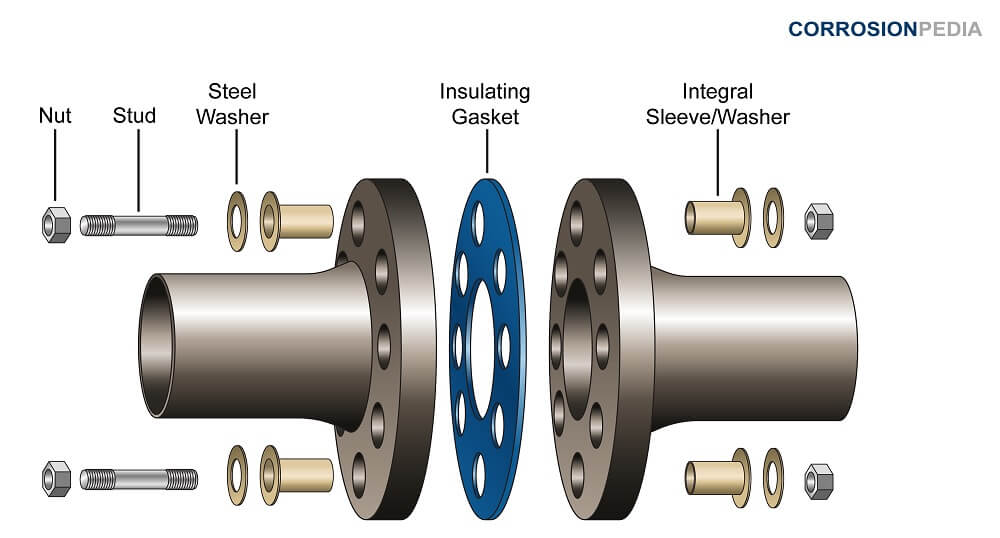

Flange isolation gasket kits are sometimes integrated into piping systems to provide an effective seal and corrosion protection of the flange while providing electrical isolation. When a phenolic gasket is placed between two sections of a pipeline, metal to metal contact is eliminated, thus preventing the flow of electrical currents and corrosion.

The plastic sleeves and washers that are used when installing a phenolic gasket provide an additional layer of protection against dielectric corrosion, which can occur when two dissimilar metals are joined. There are various types of phenolic gaskets, including ring gaskets, ring type joint, O-ring and full-face gaskets, which cover the entire face of a flat-surface pipe flange and is aligned with the bolt holes.

Phenolic gaskets are made of compressible rubber to ensure that they provide a tight seal.

In the automotive industry, extra performance can be achieved by incorporating a phenolic intake gasket into bolt-on engine modifications because it protects these add-ons from wear and tear and unwanted corrosive liquids, and provides more cold air intake that improves engine performance.

Figure 1. A phenolic gasket is placed between the flanges of connected pipes.

Corrosionpedia Explains Phenolic Gasket

Gaskets are best suited for low-pressure pipe flanges with all gasket specifications usually sized to meet standard measurements.

For the automotive industry, the additional cold air intake phenolic intake gaskets allows cars to produce more horsepower (about 5 to 10 horsepower), while adding a factor of safety to altered engines by decreasing the risk of predetonation. The phenolic intake gasket sits between the engine block and the air intake manifold, and serves as a seal between these two components, which keeps intake air from leaking out. These gaskets are made from a phenolic material, usually plastic created by layers of material laminated with a phenol or aldehyde resin. This results in a durable thermally insulating gasket.